Sewage Pump

- Sinoflo

- China

- 15-30days as per different pump material

Technical Parameter:

-Max. Capacity: 8000m3/h;

-Max. Head: 100m;

-Power Supply: 380V/220V~660V/3KV/6KV/10KV, etc.,

-Frequency: 50Hz/60Hz

Application

The pumps are widely applied in the pumping of sewage and solid waste containing particles and fiber for chemical, petroleum, pharmaceutical, mining, paper-making, cement, steel-making, power generation and coal processing industries as well as water supply and sewage system of municipal sewage treatment plants, municipal engineering and construction sites. They can also be used to pump clear water or corrosive medium.

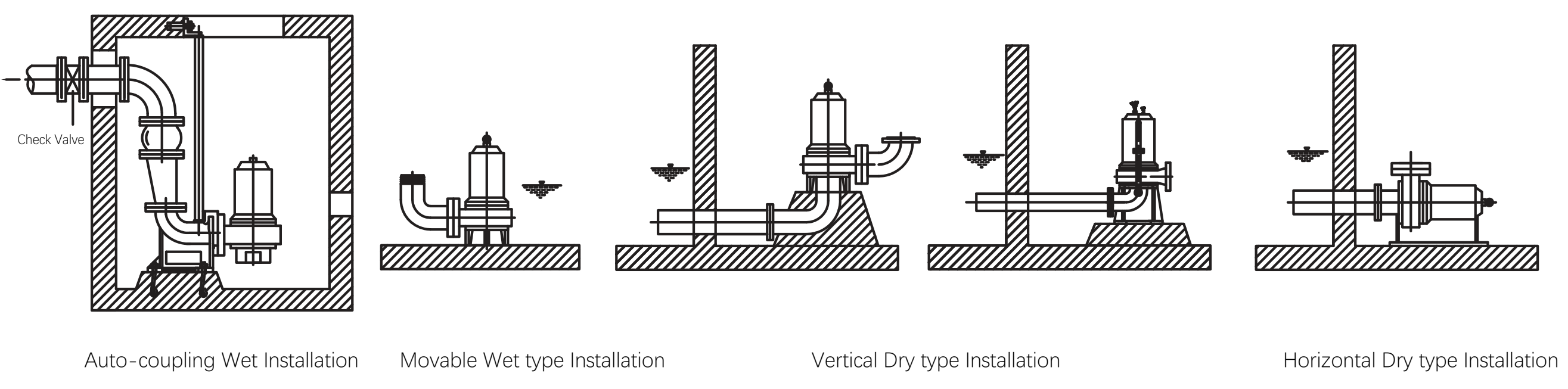

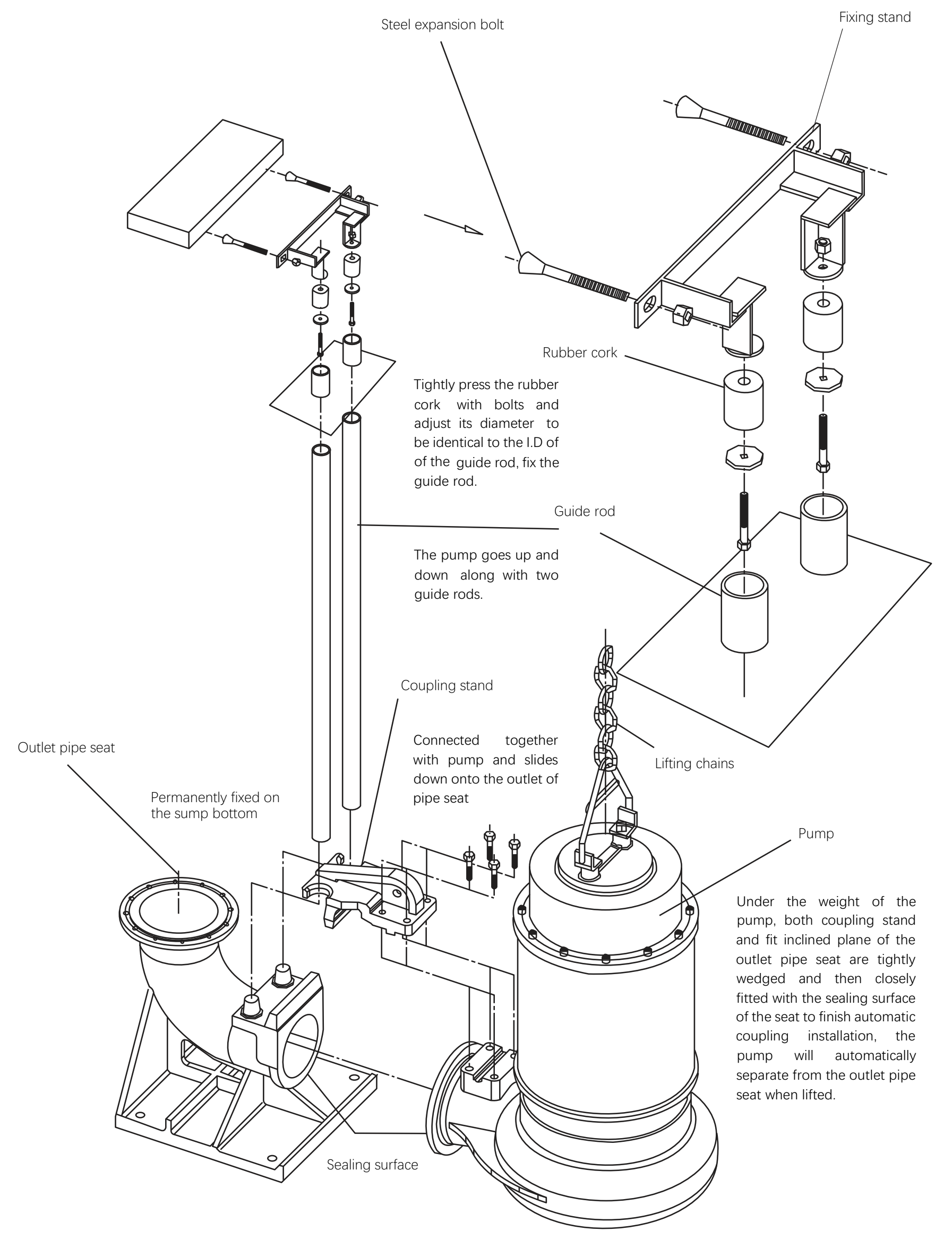

Sewage Submersible Pump Installation Method:

Working Condition

Temperature of pumped medium≤40℃; Maximum depth: 20m; PH: 4~10; Density<1150kg/m3; Solid volume ratio≤5%;

Special working medium, such as high temperature, slightly corrosive, sea water and others can be customized.

Structure Feature

The international advanced Ansys-CFX software is adopted in the optimization of hydraulic parts so as to improve hydraulic performance of the pumps and raise their efficiency to a world-leading level.

The international advanced Ansys software is adopted in the scientific calculation and analysis of pump structure so as to extend the service life of bearings and mechanical seals and reduce vibration and noise.

Pumps used on medium with rich fiber content are arranged with cutting and tearing devices at the inlet to prevent clogging and jamming which may cause severe vibration when pumping medium containing fiber and solid particles. Large-channel anti-block hydraulic parts, which allow max. solid diameter 125mm to pass through smoothly.

The cable outlet adopts a unique structure to avoid water leakage, electric leakage, short circuit and stator coil burning caused by human pulling, cable jacket damage or cable aging, thereby effectively reducing the probability of malfunctioning caused by flooding in the upper part of pump.

Considering all conditions that may take place during starting and operating, a number of warning sensors are installed inside the pumps to monitor conditions such as leakage in wiring chamber, motor cavity and oil house as well as temperature rise in upper and lower bearings and motor coil.

Patented structure is adopted in the pumps. Three sets of mechanical seals are used inside the pumps. A buffer chamber is added. The small amounts of water caused by normal leakage in the seal of the lower shaft accumulate in the seal buffer chamber. With the protection of the three sets of high-quality mechanical seals and the large accumulating capacity of the buffer chamber, sealing is made significantly more reliable to completely ensure the reliable operation of pumps.

Submersible pumps of 22kW and above adopt self-circulation cooling system to ensure continued working when motor is elevated above water.

Sinoflo is the leading supplier of all kinds of pumps to be used in agriculture, industrial etc. Surface pumps These are hydraulic machines suitable to work in a dry and covered surface They must not be immersed into liquid to move. This kind of product includes single or multi stage pumps for horizontal or vertical operation. Circulator and in-line pumps Very similar to the surface pumps, m...more