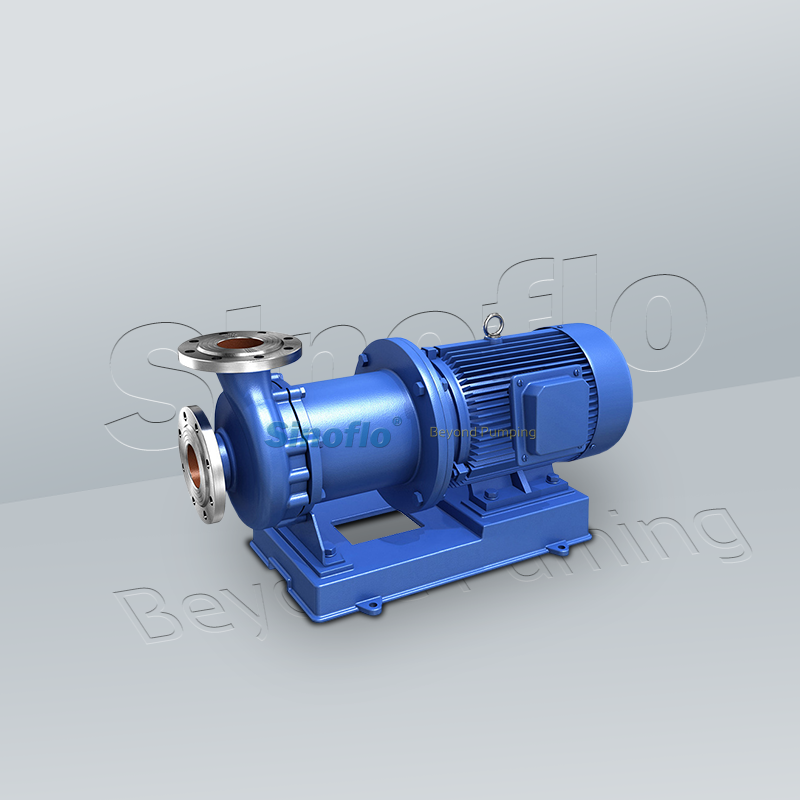

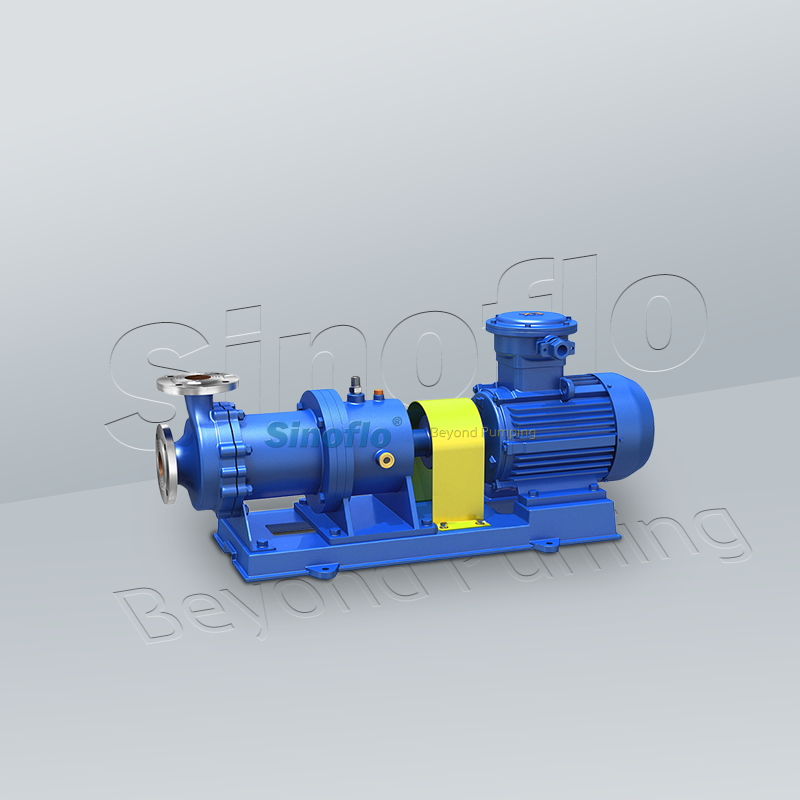

Standard Sealless Magnetic Pump

- Sinoflo

- China

- 15-30days as per different pump material

Technical Parameter:

-Max. flow capacity: 120m3/h;

-Max. head: 125m;

-Max power: 75kW;

-Max. medium temperature: 200℃;

-Design pressure: 1.6MPa;

-Material: S.S304/304L/316/316L/HC276/TA2, etc.

Product Overview

Sinoflo Standard Sealless Magnetic Centrifugal pump (referred to as magnetic pump), usually consists of motor, magnetic coupling and corrosion-resistant centrifugal pump. Its main feature is that the magnetic coupling is used to transmit power, no leakage. When the motor drives the outer magnet of the magnetic coupling to rotate, the magnetic lines pass through the gap and the isolating sleeve, and act on the inner magnet to make the pump rotor and motor rotate synchronously. Transmit torque without mechanical contact. At the power input end of the pump shaft, since the liquid is enclosed in a stationary isolating sleeve, there is no dynamic seal and therefore no leakage.

Application

Petroleum, chemical, pharmaceutical, smelting, electroplating, environmental protection, food, film and television printing, water treatment, national defense and other industries;

Transport flammable, explosive, volatile, toxic, rare and precious liquids and various corrosive liquids;

Technical Parameter

Max. flow capacity: 120m3/h;

Max. head: 125m;

Max power: 75kW

Max. medium temperature: 200oC

Design pressure: 1.6MPa;

Material: 304/304L/316/316L/HC276/TA2, etc.

Notes

Cooling and lubrication of the magnetic pump bearing depends on the conveyed medium, dry run is absolutely forbidden. Avoiding idling operation caused by restarting after a power failure in the middle of the work.

If the conveyed medium contains solid particles, a filter should be added to the inlet of the magnetic drive pump; if it contains ferromagnetic particles, a magnetic filter should be added.

The ambient temperature of the magnetic drive pump during use should be less than 40℃, and the temperature rise of the motor should not exceed 75℃.

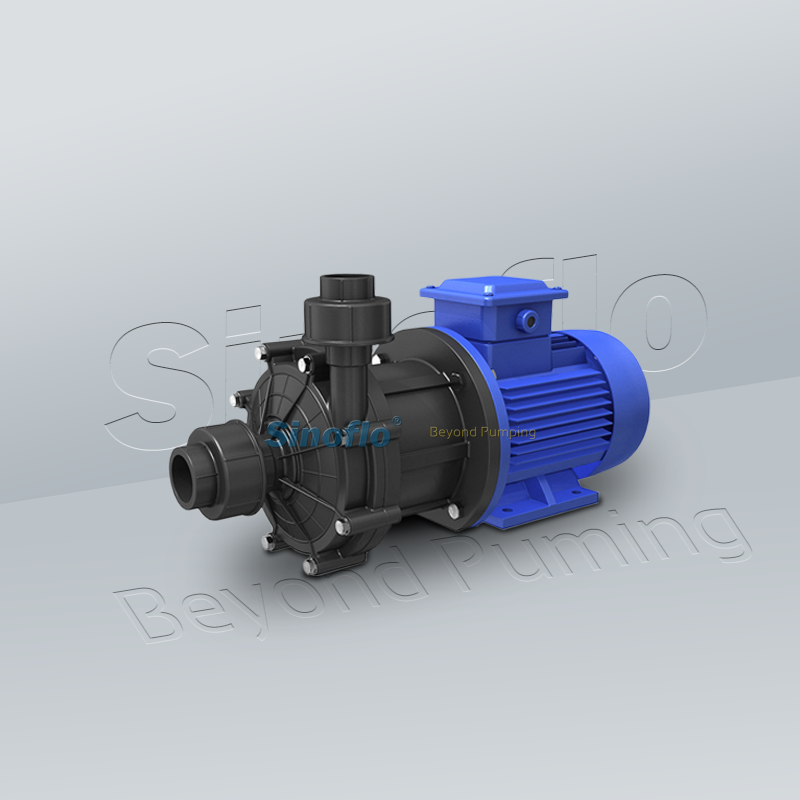

The medium to be transported by the magnetic drive pump and its temperature should be within the allowable range of the pump material. The working temperature for engineering plastic pump should be less 60℃, and metal pump below 100℃.

Transport the liquid without hard particles and fibers with suction pressure not greater than 0.2mpa, maximum working pressure 1.6mpa, density not greater than 1600kg/m3, and particle size not greater than 30 × 10-6m2/s.

The magnetic drive pump is a medium that is easy to precipitate and crystallize. After use, it should be cleaned in time to drain the liquid accumulation in the pump.

After the magnetic drive pump has been running for 100 hours, the wear of the bearing and the end face moving ring should be disassembled and inspected, and the wearing parts that are not suitable for reuse should be replaced.

Sinoflo is the leading supplier of all kinds of pumps to be used in agriculture, industrial etc. Surface pumps These are hydraulic machines suitable to work in a dry and covered surface They must not be immersed into liquid to move. This kind of product includes single or multi stage pumps for horizontal or vertical operation. Circulator and in-line pumps Very similar to the surface pumps, m...more