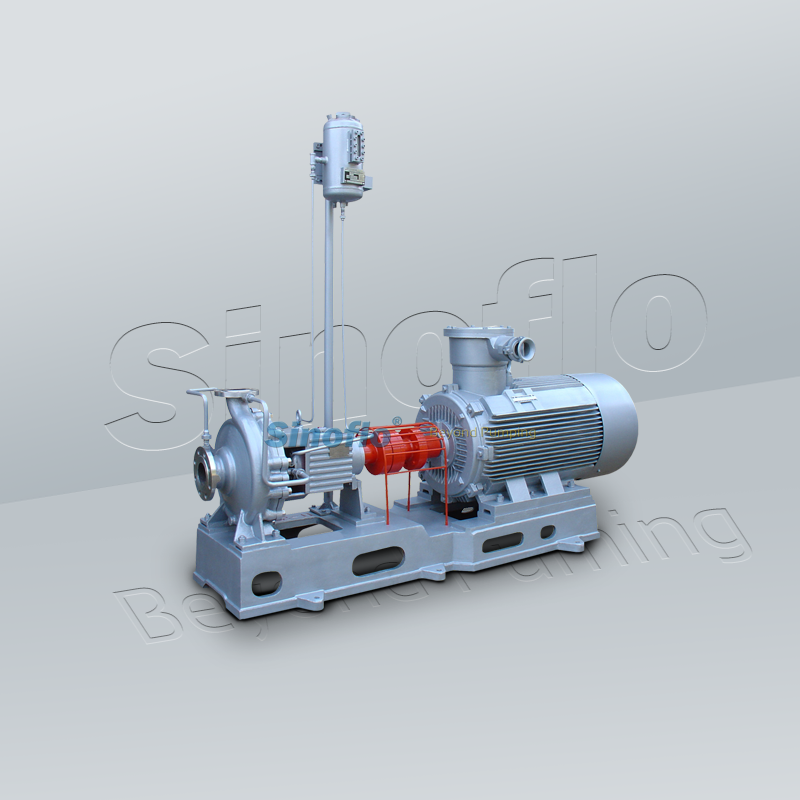

Chemical Processing Pump OH2

- Sinoflo

- China

- 15-30days as per different pump material

Technical Parameter;

-Flow rate Q: ~2600m3/h;

-Head H: ~ 300m;

-Design temperature T: -80°C~450°C;

-Design pressure P: ~5.0MPa;

Pump type: API610 OH2

Application

Soda and inorganic salts: ammonia salt blending, soda manufactured by ammonia soda process, pure soda, caustic soda manufactured by diaphragm process and ion exchange membrane process, chloride and hypochlorite, soda sulfide, sulfate, hydrogen peroxide, etc.

Metallurgy: electrolyte of electrolytic copper and nickel, sodium aluminates liquid for aluminum production, acid for cobalt production, or slurry for zinc production, ammonium vanadate for vanadium production, acid and thiocarbamide liquid for gold production, etc.;

Iron and steel industry: electroplating, souring, electrophoresis painting, etc.

Acid-making industry: hydrochloric acid, nitric acid, sulfuric acid, phosphoric acid, phosphoric acid pulp, acetic acid, etc.

Petrochemical industry: petroleum’s refining, splitting and separation, butadiene alkylbenzene, carbinol, etc.

Fiber and plastic industries: Dacron, dichloromethane, epichlorohydrin, trichloro propane, PVC, DMF, etc.

Paper-making industry: pulp digestion liquor, green liquor, white liquor, concentrated black liquor, bleaching liquor, etc.;

Chemical fertilizer industry: urea, ammonium nitrate, ammonium bicarbonate, ammonium chloride, ammonium phosphate, potassium chloride, potassium sulfate, etc.;

Fermentation industry: intermedium, lactic acid, citric acid, food additives, beer, various fermenting liquor, etc.;

Environmental protection: various chemicals, wastewater containing acid and alkali, etc.;

Technical Parameter

Flow rate Q: ~2600 m3/h

Head H: ~ 300m

Design temperature T: -80°C ~ 450°C

Design pressure P: ~5.0MPa

Application

Clean or contaminated, low temperature or high temperature, chemically neutral or corrosive liquid;

Refineries, petrochemicals, chemical industries, coal chemicals, desalination, power stations, fertilizers, pulp and paper, offshore platforms and general industrial applications.

Features

Single stage radial impeller, horizontal, radial split volute, foot or centerline mounting. Axial suction, radial discharge, suction and discharge flange pressure levels are the same. The pump body and impeller have a replaceable seal ring that balances the axial force in the pump through the balance hole. The shaft seal and auxiliary system piping configuration adopts API682 standard mechanical seal and flushing scheme. Various cooling methods such as natural cooling, air cooling, and water cooling can be configured according to working conditions.

Sinoflo is the leading supplier of all kinds of pumps to be used in agriculture, industrial etc. Surface pumps These are hydraulic machines suitable to work in a dry and covered surface They must not be immersed into liquid to move. This kind of product includes single or multi stage pumps for horizontal or vertical operation. Circulator and in-line pumps Very similar to the surface pumps, m...more